Adsorption Behaviors Of Bioadsorbents For Metal Ions

All of the bioadsorbents prepared by the method mentioned above exhibited extraordinary high selectivity only to gold in the adsorption from hydrochloric acid solutions. For example, Figure 2 shows the % adsorption of some metal ions onto bioadsorbent prepared from orange waste from various concentrations of hydrochloric acid solution , where the % adsorption denotes the percentage of metal ion adsorbed on the adsorbent from aqueous solution and defined by the following equation.

Figure 2.

Percentage adsorptions of some metal ions on bioadsorbent prepared from orange waste by treating in boiling concentrated sulfuric acid .

As seen in this figure, only gold is quantitatively adsorbed over the whole concentration range of hydrochloric acid tested, while other metal ions, not only precious metals such as palladium and platinum but also base metals such as copper and zinc, are not practically adsorbed. Similar phenomena were also observed also for all bioadsorbents prepared by the method using boiling concentrated sulfuric acid.

Figure 3.

Percentage adsorptions of some metal ions on bioadsorbent prepared from orange waste by means of carbonization at 800°C.

Figure 4.

Thiourea Leaching With No Preliminary Treatment

Thiourea leaching tests were firstly carried out under the following operative conditions: thiourea 25 g/L, Fe3+ = 0.6% w/v, H2SO4 0.1 mol/L , L/S ratio 10, T 25 °C, and stirring 250 rpm . The effect of leach time and of the size of PCBs on gold dissolution was studied.

The results reported in show that gold extraction was negligible in any condition and did not reach 12%, contrary to what was reported by Li et al. .

The Second Chemical Bath Refining Your Gold Foils

THIS STEP SHOULD NEVER BE ATTEMPTED without your CHEMICAL MASK.For this chemical bath I will be reproducing the process on small scale. this is by far the most hazardous step and with the most reactive wastes.For this step I am going to use a 100 ml beaker a portion of recovered foils, about 3 grams.I will be using Muratic acid, and clorox.I will be adding only enough Muratic acid to cover my 3 grams of foils, Using a Pipette I will slowly add Clorox until all of my foils have dissolved. you can use a glass rod to help felicitate the process.After your foils have dissolved the resulting solution will be a deep golden yellow maybe a little orange in color.it may be desirable to filter your solution with the coffee filters 1 more time, depending on if little bits of green plastic from the board found their way into this step.

You May Like: 18k Gold Price Calculator

Selecting Materials To Be Recovered

I was taught by the method of Crap in Crap out. You want your materials to be as clean as possible with the least Amount of Garbage as possible. Gold fingers are typically found on PCI cards, ISA cards, or on Memory sims/dimms/etc. They create the corrosion free connection between the computer and the expansion card. This process can also be used to recover gold from CPU such as Pentium Pro, or Cyrix or older 486 and lower generation chips.

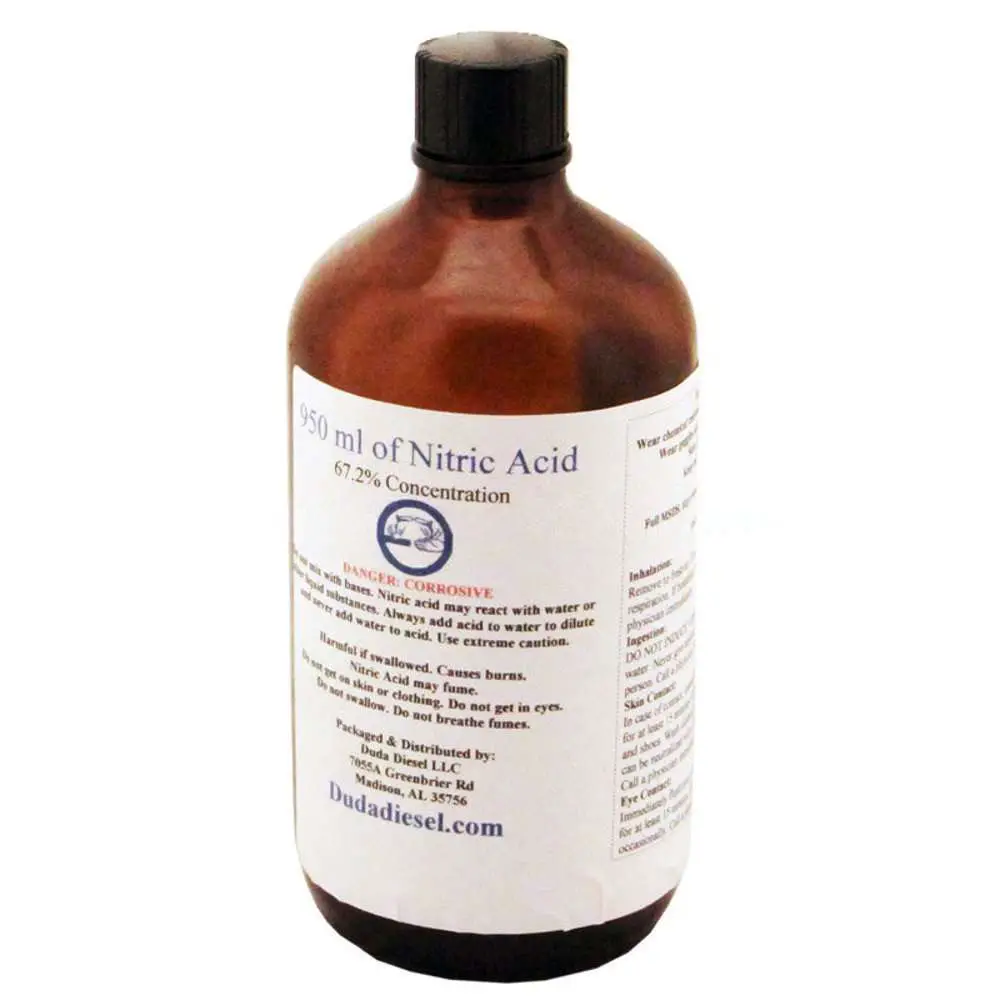

Nitric Acid Suppliers Usa

Nitric Acid also known as:

Aqua fortis and spirit of niter, is a highly corrosive mineral acid. UN Number: 2031. CAS number: 7697-37-2. : HNO3.

Where to buy Nitric Acid in the USA

We have compiled a list of Nitric Acid suppliers in the USA, the companies listed have a genuine United States presence and include: manufacturers, distributors, wholesalers, industrial, retail and bulk suppliers. Use the suppliers website link for prices, more information or to purchase. To find other products or services, use the search box. Alternatively search: Australia, NZ, UK.

Read Also: War Thunder Free Golden Eagles App

Find Many Great New & Used Options And Get The Best Deals For 16oz Nitric Acid 70 Concentrated Acs Lab Grade Best For Gold Silver Refining At The Best Online Prices At Ebay

Where to buy nitric acid for silver recovery. This chemical ships only within the lower 48 us states using standard ground. 1 liter concentrated nitric acid hno3 70% v/v laboratory grade. 48 $29.91 with subscribe & save discount.

Eisen + swiss 70% nitric acid hno3 top laboratory acs reagent grade . Buy 475 ml / 16 oz of 67.2% nitric acid industrial grade for gold refining metal recovery platinum silver at walmart.com 250 ml low form borosilicate glass measuring lab.

For sale is two 32oz glass bottles of 70% nitric acid, hno3. Free shipping free shipping free shipping. Buy 10 liters / 2.64 gallons of 67.2% nitric acid industrial grade for gold refining metal recovery platinum silver at walmart.com

Get it as soon as tue, sep 21. This way i avoid over boil and over heating. When i am using this acid, i cut it with 10 to 1 distiled water.

Of 70% nitric acid, hno3 in a glass bottle. You can look it up. A simple adjustable bullet casting pot should be hot enough.

If my memory is correct silver melts at about 1100 farenheit. We supply nitric acid in various grades, including analytical, general and technical grade. Buy 475 ml / 16 oz of 67.2% nitric acid industrial grade for gold refining metal recovery platinum silver at walmart.com

Aqua regia, dt chemicals, 32oz. When i am using this acid, i cut it with 10 to 1 distiled water. Nitric acid 70% hno3 maximum strength + highest purity acs laboratory reagent grade.

recover gold from computer parts at home RGFCPAH12320GS in

Gold Silver And Sodium

An alloy was then taken consisting of:

Gold 64.7Silver 23.4Sodium 11.9

This was boiled in dilute, then in strong sulphuric acid, gave gold 988 fine this when fused with sodium bisulphate gave gold 993 fine. This shows that a very small amount of sodium is sufficient for parting with sulphuric acid. The alloy requires such a low temperature for melting, and parting can be done so easily, and there is no impurity introduced which cannot easily be eliminated. With sodium at a low price the method of parting could be advantageously practised in many cases.

Don’t Miss: War Thunder Free Eagle

Ing Of Gold And Silver Commercially

Gold is not soluble in sulphuric acid except when nitric acid or some other oxidising agent is present. In this case it is again precipitated on dilution with water. Neither platinum nor palladium are dissolved when these are present in a silver alloy.

Copper is dissolved when alloyed with silver, but owing to the insolubility of copper sulphate in strong sulphuric acid the action is either retarded or prevented. Copper, also, owing to its low equivalent, consumes nearly three and a half times as much sulphuric acid as silver.Zinc behaves in a similar manner to copper.

Iron is also slowly attacked, white iron, containing phosphorus, being less attacked than grey pig. The sulphate of iron formed is insoluble in strong sulphuric acid.Tin and antimony are also dissolved, but form basic salts on dilution.

Lead is slowly attacked, if in large quantities, but in small it dissolves readily. If present in excess lead sulphate separates out from strong acid solution. On dilution with water the lead sulphate dissolved by the strong acid is thrown down.

Outline of the sulphuric acid process as originally used in the New York assay office. The process comprised eight operations:

Ing Of Zinc Silver And Gold

Since the removal, not of zinc, but of silver is aimed at in parting, an alloy consisting of:

Gold, 9.000,Silver, 1.000,Zinc, 10.000,

was fused in a porcelain crucible under a layer of potassium cyanide. After cleaning the button, it was boiled for half an hour with 20cc of 2 of nitric acid to 1 of water. The zinc dissolved first, and white silver-like crystals appeared on washing with water after first treatment by acid. The button became fissured. The acid was poured off, and 10cc of 1 to 1 acid put on and boiled for about 15 minutes finally 5cc of strong nitric were applied. The button was washed, dried and weighed. The weight of gold was 9023. It was then wrapped in sheet lead and cupelled. The final weight was 8885. In this case, as in the previous one, some solution of the gold takes place, even although the whole of the zinc was not removed.

The ratio of the gold-zinc alloy would give a formula approaching Au. Zn3, which seems to be sufficient for parting. It therefore follows that zinc could be substituted for silver in this operation. It has the advantage of being cheap, of forming an alloy at a low temperature, and even when in small proportions it reacts vigorously with nitric acid.

Don’t Miss: War Thunder Golden Eagles App

The First Chemical Bath

Objective of this first chemical bath is to remove a large majority the base metals, Such as nickle, zinc and copper. After cleanly removing your plated sections of computer parts. remove any visible capacitors transistors, or other components. be sure to also remove any steel or iron parts attached. These metals can foul the reaction causing poor results.Tools 100 ML beaker, 1 gallon bucket, 2 1/2 gallon bucket. Chemicals Muratic acid, and hydrogen peroxide. Materials you are looking to recover. First step, place your 1 gallon stainer bucket, into your 2 1/2 gallon wash bucket. But first place your parts to be recovered inside your 1 gallon strainer bucket. as pictured. Add enough muratic acid to cover your fingers about 1 cm above your materials. keep track of how many MLs are added. you want to keep your waste Acids to a minimum. second. To activate the solution you want to add your Hydrogen peroxide 3 – 5% solution in a 2 to 1 ratio. two parts muratic acid to one part hydrogen peroxide. after the Peroxide has been added to your muratic acid the mixture should start to bubble, and the base metals should begin to dissolve. At this point you should be wearing your safety gear because a few unfriendly fumes are being released. This process can take up to 24 – 48 hours. this works best at the temperatures of 80 – 90 F. When this has been completed you will see a batch of gold foils floating in your now dark green acid.

Sourcing Nitric Acid In The Uk

Emporio said:I had the same problem. The only way to buy nitric acid in Scandinavia is to have a permit from the government. The application fee for the permit is a little over 80 USD and there is no guarantees that you will get the permit either. Much like in the UK.One alternativ is to make your own nitric acid by destillation using one part calcium nitrate Ca2, and two parts sodium hydrogen sulfate NaHSO4. No license is required for these two chemicals here, I don’t know how it is in the UK. One is used as fertilizer and the other is used for lowering the pH in pools.

Read Also: How Much Is Spectrum Gold Package

Recovery Of Gold From Mongolian Gold Ore

At present, majority of gold has been recovered from gold and silver ores by means of cyanide process developed at the beginning of twentieth century as schematically shown in Figure 14. In this process, pulverized ores are leached using alkaline cyanide solution to extract gold as gold-cyanide complexes according to the following reaction:

Figure 14.

Flow sheet of conventional gold recovery process from gold ores using alkaline cyanide solutions.

The extracted gold as anionic species, AuCN2â, is adsorbed onto activated carbon or strongly basic anion exchange resins, which are termed as CIP and RIP processes, respectively. Because it is difficult to desorb the gold adsorbed onto these adsorbents, these are incinerated at high temperature to recover metallic gold.

This cyanide process has suffered from some problems as follows:

Strong toxicity of cyanide, which causes serious environmental problems and, consequently, needs some costs for safe operation and environmental protection.

Interference by other coexisting metals or low selectivity over other metals.

Slow dissolution of gold as shown in Table 2 that shows the comparison of dissolution rate of gold by some lixiviants.

| Reagents or mixtures |

|---|

Refining Gold With Sulphuric Acid

Pure silver is readily attacked by strong hot sulphuric acid of SG 1.815, or about 90 per cent, strength. The reaction which takes place may be represented as follows:

2Ag + 2H2 SO4 = Ag2 SO4 + 2H2O + SO2

Silver sulphate so produced is very soluble in the strong acid, when it is hot, as little as one-fourth of its weight of sulphuric acid being sufficient. As a matter of fact, on applying the acid the bisulphate of silver forms which melts at a comparatively low temperature.

2Ag + 3H2SO4 = 2Ag HSO4 + 2H2O + SO2

When the melted mass is cooled the bisulphate crystallises out. By pouring the solution out into water a copious white precipitate of the bisulphate forms. If, however, the solution is carefully diluted by means of steam to about a sp. gr. of 1.65 or 73 per cent, sulphuric acid, and allowed to cool, hard yellow crystals of anhydrous silver sulphate are precipitated. The same crystals may be obtained by allowing an aqueous solution, or one of dilute sulphuric acid, containing the bisulphate in solution to cool down a deposit of yellow crystals of Ag2 SO4 will form.

Dr. Percy states that one part of silver sulphate requires for its solution.

Don’t Miss: What Can You Mix With Bacardi Gold

Recovery Of Gold From Simulated Spent Cyanide Solutions Using Bioadsorbents

As mentioned earlier, cyanide solution has been extensively employed for a long time in gold mining and also in plating applications because of its special complexing capabilities in aqueous solutions, creating the soluble Au2â complex. Also as mentioned in the preceding section, such Au2â complex is recovered by means of adsorption on activated carbon or strongly basic anion-exchange resin. However, such adsorptive recovery of gold is not always quantitative and trace concentrations of gold still remain in the cyanide solution. Spent cyanide solutions generated after the recovery of gold are treated for cyanide decomposition before discharging in environments according to the following processes :

Oxidative decomposition using sulfur dioxide

In this process, cyanide ion is decomposed by the aid of sulfur dioxide and oxygen gasses blown into the cyanide solution catalyzed by cupric sulfate according to the following reaction:

The recovery of trace concentrations of gold remaining in spent cyanide solutions has been difficult due to relatively high processing costs as well as other various technical problems. However, the recovery of such trace concentration of gold has become highly attractive from an economical point of view due to the high price of gold in recent years. Consequently, we attempted to recover such trace concentration of gold from waste cyanide solutions.

Figure 18.

Figure 19.

Preparation Of Bioadsorbents For Gold Recovery

The bioadsorbents for gold recovery can be easily prepared in a simple manner as schematically shown in Figure 1. Pieces of feed materials of biomass are stirred in boiling concentrated sulfuric acid for about 24 h, where hydroxyl groups contained in the biomass undergo dehydration condensation reactions and polymer chains of the biomass are cross-linked via ether bonds. The solid materials are neutralized using dilute alkali solution and water-washed and then, they are dried in a convection oven and pulverized. Finally, they are sieved to uniform the particle size. The final products are black powder, the particle size of which are less than 0.1 mm.

Figure 1.

You May Like: One Brick Of Gold Worth

Recovery Of Gold From Printed Circuit Boards Of Spent Mobile Phones

As an example of the use of bioadsorbents we prepared, recovery of gold from printed circuit boards of spent mobile phones is introduced in this section.

Spent home appliances such as mobile phones are dismantled by hand work into various parts to recover various valuables for their reuses as shown in Figure 10.

Figure 10.

Flow sheet of the dismantling of spent mobile phones.

Of these dismantled parts, gold and other precious metals such as palladium and platinum are contained in PCBs i.e., PCBs of spent electronics are typical secondary resources of precious metals. According to the conventional recovery process of precious metals from complex feed materials such as anode slimes of copper and nickel generated in electrorefining processes of these metals which contain many kinds of metals such as gold, silver, palladium, platinum and base metals, they are recovered by repeating dissolution using aqua regia followed by precipitation for many times, which needs tedious long-time operations and high labor costs. In early 1970s, new recovery process was developed and commercialized by INCO . In this process, the feed materials are totally dissolved in hydrochloric acid into that chlorine gas had been blown, abbreviated as chlorine-containing HCl, hereafter. Here, the chlorine gas dissolved in hydrochloric acid solution is converted into hypochlorous acid according to the following reaction:

Figure 11.

Flow sheet for the treatment of spent PCBs in the present work.

Figure 12.

Testing Your Solution For Gold

Ok, this is the exciting part and one where you get to see some real chemistry at work..you will need:Stannous cloride created earlier, 1 coffee filter paper, 2 pipettes or glass droppers.Simply place 1 dot of recovered solution on a piece of filer paper, Next place one drop of your stannous cloride on the other. The resulting reaction should turn purple.If your did CONGRADS you have created AURIC Cloride Or Aucl3 a gold bearing solution. If your test drop didnt turn purple, add a little more tin to your stannous cloride and heat gently with a alcohol burner and BOROsiicate test tube. Repeat Test.depending on how much gold is in your solution it may appear black.

Don’t Miss: What Does Bacardi Gold Mix Well With