Bank Safe Deposit Boxes

Using the safe deposit box in a bank is a good and affordable option. You can get the smallest box for as low as $50 and the biggest for $200 per year.

However, when storing, keep time in mind. Gold is the most liquid metal. But some gold forms are more liquid than others.

A bullion coin sells faster than other forms. You can take it from the box and sell it at any time without an assay.

You should also consider working hours. Storing your gold in a bank means you have to work with the banks hours. So if you need it urgently after the bank closes, you may have to wait until it resumes its official hours.

Why Do We Need To Refine Gold

The answer is very simple: We cannot use gold in its raw form. It is a precious, noble metal that comes in different forms: As an alloy of silver and platinum, an amalgam, as a part of a stone, or in scattered particles. Or you may even decide to refine your current piece of gold and convert it into another shape/form that will be more useful for you.

Gold must be refined from its alloys or amalgam forms in order to get the pure gold that you can use in whichever way you like. Several people think that their gold pieces are pure. That may not be true, because an alloy of gold and copper still have a brilliant shining color, but it lacks other chemical properties of gold.

When gold is refined, this process increases its value and market worth. More so, it helps in the preservation of this noble metal because when exposed to some chemicals, gold could be oxidized.

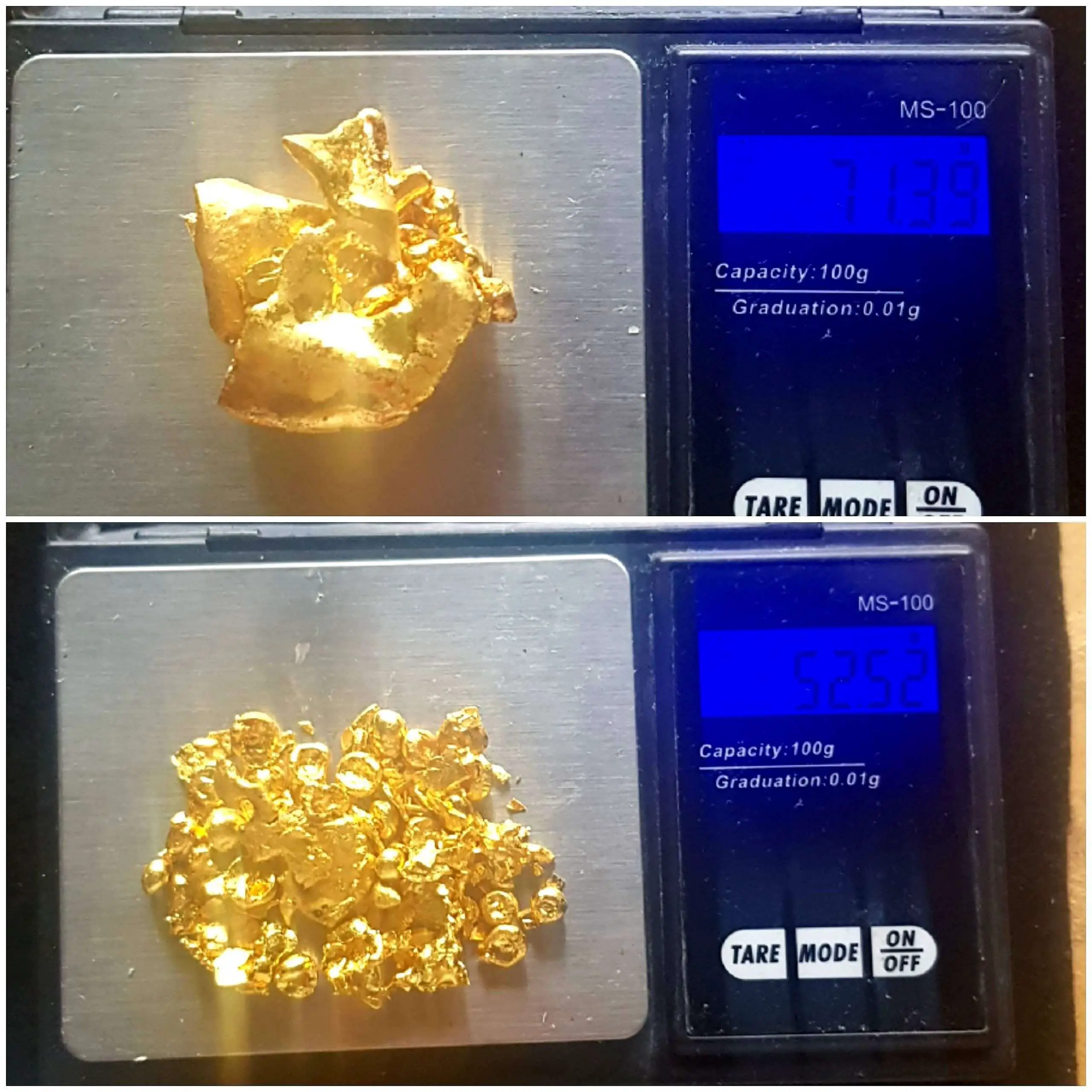

How To Calculate The Value Of Gold Scrap

As we talked about before, scrap gold comes from many different sources, and its quality is different according to the industry. Gold from computers, electronic devices, dental scrap, implants, and jewelry all have a variable karat, depending on the object and the composition.

If you have any gold to refine and want to know its estimated value before sending it in, here we give you a couple of resources that can help you.

At the time of sending, if you know the purity of the scrap gold you have, you could use our scrap gold calculator and get a free estimation, and check the information here where we explain how easy it is to use the calculator. This way, you will get an estimation of the value of your material, with live scrap gold prices. Remember that it is just an estimation, providing a close to exact calculation, but then you need to consider that the gold refinery you use will have different charge fees. Depending on the volume of gold scrap, gold refineries charge different percentages or flat fees.

If you generate scrap gold, we could send you a container so that you can start recycling your gold with us.

The reality is that if you generate any type of scrap gold, it is possible that you could be adding other types of metals that are also valuable. Please connect with one of our experts to find out if your industry uses other types of precious metals and what we could do for you.

Recommended Reading: How Much Is 14k Italy Gold Worth Per Gram

The Refiner Separates The Gold And Lead

Once everything has cooled down, the refiner removes the lead button and places it in a porous cup known as a cupel. The refiner will then heat this in a cupellation furnace. When the cupel is heated, the lead seeps out through the porous holes in the cupel, leaving behind just the gold in a bead-like shape. This bead of gold is known as the prill. To separate the gold from the silver, the refiner places the gold bead in nitric acid or a combination of hydrochloric and nitric acids.

Order A Container From Pease And Curren Today

If your business deals with gold in any way, youll want to have a safe and secure way to transport it. At Pease and Curren, we offer the perfect solution.

Our containers provide an excellent way to transport and ship your gold, and we offer them in a wide range of sizes. We offer a small jar , a large jar , a keg , a small drum , a large drum and a pail . If youre unsure about what size you need, call and chat with us and let us help you decide.

At Pease and Curren, we believe in delivering high-quality results, treating our customers with respect and implementing honest and upstanding business practices. Weve been in business for more than 100 years and have been trusted for generations. Were based in Rhode Island, but we serve the entire country and most of North America. If youre a pawn shop, a jeweler or any other type of business in need of a gold refiner, we hope youll join the legions of customers whove been wowed by our work.

If you have any questions about ordering a container or about our services or business, feel free to contact us with our online form or give us a call at 401-739-6350.

Also Check: How To Get Free Gold Bars In Candy Crush

Advantages And Disadvantages Of Aqua Regia

Aqua Regia is a well-known process for obtaining gold in its pure form. And the chemical reactions involved in this procedure are effective. The chemicals are available everywhere and not too expensive.However, the main disadvantage of this procedure is that permissions from the local authorities may be needed. This is because some of the chemical reactions may produce by-products that could have some destructive effects on the environment. This include toxic fumes and chemical by-products that may not be good for human health.

Refining Your Scrap Jewellery

Historically, Gold and Silver have widely been used in manufacturing Jewellery in addition to being used as currency. Both precious metals carry desirable traits for the manufacturing of jewelry. Jewelry manufactured with Gold is unlikely to tarnish while Silvers beautiful shine also invites manufacturers. In order to manufacture strong jewelry, an alloy must be created by mixing other metals. Both Gold and Silver are much too soft in their pure form to be used in jewellery manufacturing. Both metals have a recognised scale to measure the purity

Gold Purities

.800 Silver: At least 80% Silver & no more than 20% copper or other metals.

.925 Sterling Silver: At least 92.5% Silver & no more than 7.6% copper or other metals.

.950 Sterling Silver: At least 95% Silver & no more than 5% copper or other metals.

Fine Silver: 99.9%

Regardless of the fact that the precious metals are tainted by impurities, the jewelry continues to carry value. Higher concentrations of Gold and Silver in jewelry will inevitably lead to a higher payout once refined.

How to Refine and Sell your Scrap Jewelry

Should you have any inquiries regarding our rates or our refining process, feel free to contact us. You can reach us via email, live chat, social media, or you can call us at +1 604-498-5001!

Recommended Reading: Where To Sell Valuables In Rdr2

How Gold Is Refined: A Step

Have you ever wondered what happens to your jewelry after you sell it? Certainly, you get paid in most cash-for-gold operations, but what happens to the gold itself? What is it good for and why are people willing to pay for it in the first place?

At Pease & Curren, we understand that its important for you to be well informed about the decisions you make. Thats why weve put together a step-by-step guide on what happens to the gold in your old jewelry after you sell it.

Refining Gold Jewelry Scraps

When questions arise about manufacturing quality gold jewelry, manufacturers are eager to talk shop with their peers and industry experts. They want to know if they are using the right alloy for a specific application, casting at the appropriate times and temperatures, and annealing properly when work hardening a piece.

Rarely, though, does the conversation turn to refining, an area of jewelry manufacturing that poses more questions than answers in many manufacturers minds. Refining is a practice that must be done precisely and methodically to ensure the full recovery of gold, as well as an end product that is free of impurities, which can lead to quality problems when the metal is reused in production.

But refining doesnt have to be a mystery to manufacturers. There are several methods commonly used to recover metal. Some operations are suitable for use by manufacturers and jewelers who wish to refine in-house, while others are designed for commercial refiners who handle large lots. The following are the most common methods used in the jewelry and gold refining industries.

Recommended Reading: How Much Is 10k Gold Worth

How Does A Gold Refinery Work

It is important to note that a gold refinery is a precious metal refinery, so if you want to know more about the process of gold refining, check out this article where we explain what a precious metal refinery is and how it works.

On your side, we make the process very simple:

- We will send you the container/s for free with return shipping labels.

- Whenever you are ready, give us a call, and we will schedule a FedEx pickup.

- As soon as we receive the material, we will provide you access to our customer portal where you will be able to monitor and follow our process.

- In just a few days with a quick turnaround, you will receive a check .

The Art And Science Of Refining Gold At Home

A quick tutorial in DIY chemistry.

You’d be forgiven for thinking that things like the process of refining gold are complex and complicated procedures that can only be performed in special labs and factories by seasoned and experienced professionals with a wealth of custom equipment. And if you want to do it well, fast, and in great volume, that’s probably accurate. But, in a pinch, you totally could refine some gold in your own home. It’s not even that hard.

The process, as illustrated and described in a fantastic video from Cody’s Lab, is one you might be vaguely familiar with if you paid any attention in chemistry. Simply put, the trick to refining gold is to dissolve impure gold in acid such that all the impurities fall out, and then to pull the pure gold back out of your acid solution. Practically, the process is a little bit more involved, but I’ll let Cody explain the nitty gritty details:

This is just the first part of Cody’s series on gold refinement, the second of which will repeat the process for actual jewelry. And if you can’t wait for more science, theCody’s Lab backlog includes all sorts of fun stuff like pulling the lead out of lead paint and turning urine into gunpowder. You probably shouldn’t try any of this at home, even thought this gold refinery process actually doesn’t see TOO wildly dangerous. But it’s much easier and safer to sit back, watch an expert at work, and wish that you had paid more attention in chemistry class.

Don’t Miss: How Much Is 14k Italy Gold Worth Per Gram

How To Recover Gold From Scrap

Recovering gold from scrap can be profitable, particularly when melting down jewelry to get to the raw metal. Unprocessed gold sells for less than the purified material, although you need to ensure that you’re not harming your profit margins by spending too much on the purification process. Recovering pure gold from scrap is easier than you might think. Unlike salvaging it from electronics or computer equipment, when you have pure gold scraps, the only thing you need to do is apply sufficient heat and collect what’s left. Unfortunately, most gold scraps are not pure, and require chemical treatments to refine.

Learn more about refining gold from scrap. Refining it from electronics is far more challenging, as it requires heavy chemical treatments, complex venting for safety and in-depth research. Be prepared: What you thought was gold jewelry is actually mixed with many other metals, such as silver, zinc and others.

Purchase a home refining system if you’d like to go through with the process yourself. You will also need to purchase the chemicals to run it. Track all costs to ensure that you’re making a profit from refining the scrap gold. The two primary chemicals you will need are nitric acid and aqua regia. You can purchase these from chemistry supply companies. If you do not purchase a home refining system, you will at least need a chemistry lab equipped with a hood and properly working ventilation system.

Warnings

References

Gold Recycling And Where To Refine Your Scrap Gold

The concept of Gold Refinery has been around for thousands of years, given that gold has been considered a precious commodity since its first discovery.

However, gold refineries have evolved over time, becoming more efficient and productive with the new technologies, even if some basic procedures are the same that were used centuries ago.

Recommended Reading: How To Get Free Golden Eagles In War Thunder

Extracting Gold From Scraps

Collect any gold-containing metal scraps to which you have access, including jewelry, computer processors, old telephone wiring or gold tooth crowns. Keep in mind that outdated electronics are likelier to produce parts with a high enough level of gold to make the procedure worthwhile.

Obtain the correct amount of chemicals and appropriate size containers for the amount of scrap metal you wish to refine. You will need 300 milliliters of container capacity, 30 milliliters of nitric acid, and 120 milliliters of hydrochloric acid for every ounce of metal you intend to refine.

Apply all safety gear correctly before working with any chemicals. The acids involved in this process are highly corrosive and react strongly.

Add your scrap materials and the appropriate amount of nitric acid, as mentioned above, to the smaller of your plastic containers. Wait 30 minutes before adding the hydrochloric acid. Let the chemical reaction develop overnight to be sure that all of the gold has dissolved.

Filter the particles out of the acid in the plastic container by attaching a Buchner funnel filter and pouring the remaining liquid into the larger of the plastic containers. The resulting acid will be deep green and translucent.

Heat a quart of water to boiling and add the sodium bisulphite to the boiling water in the ratio of 1 ounce of sodium bisulphate for every ounce of metal being refined. Pour this mixture slowly into the acid and wait for a reaction.

Things You’ll Need

How To Refine Gold

wikiHow is a wiki, similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 21 people, some anonymous, worked to edit and improve it over time.wikiHow marks an article as reader-approved once it receives enough positive feedback. In this case, 93% of readers who voted found the article helpful, earning it our reader-approved status. This article has been viewed 363,444 times.Learn more…

You may want to make some extra money by refining your own gold at home, or you may be a jeweler who wants to refine gold in-house. There are multiple ways to refine gold on a small scale as long as you take appropriate safety measures. This article will teach you to refine gold using the aqua regia method.

Also Check: Cheap Xbox Live Gold Membership 3 Months

Add Your Water/urea Mix To The Acid

Be sure to do this slowly, to ensure no gold particles are lost. The acid will foam with the addition of the water/urea mix.

Do not add the mix so quickly that the acid foams out of its container. When the acid stops reacting to the addition of water/urea mix, stop. This will raise the pH of the acid from 0.1 To 1.0, neutralizing the nitric acid but not the hydrochloric.

Pour The Acid Into Another Larger Container

Do not allow any particles to be poured off. If you have a filter funnel, preferably a Buchner filter funnel, use it. If any particles are poured off with the acid, they will contaminate your gold.

The acid will be an emerald green color and should be clear . If the acid is murky, it may contain particles and should be refiltered.

Read Also: How Many Grams In 1 Oz Of Gold

The Principle And Equipment For Aqua Regia

Aqua Regia has been used to separate gold from other metals for a long time. It involves using Aqua Regia, which is a Latin word for royal water. Actually, Aqua Regia is a chemical solution which fumes, and it is corrosive in nature. It is either yellow or red in color. You can freshly prepared Aqua Regia by mixing concentrated hydrochloric acid with concentrated nitric acid.Aqua Regia gets its royal name from its ability to dissolve some noble metals such as gold and platinum. The diagram below explains the Aqua Regia gold refining process:

Figure obtained from Ganoskin www.ganoskin.com

Since gold naturally occurs as an alloyin a mixture with other metalsa process such as Aqua Regia will be a good method to obtain gold in its purest form. The physical steps involved in this procedure are highlighted below:

I. The alloy consisting of gold and other metals is introduced/fed into the Aqua Regia system after it has been granulated and heated in an Aqua Regia solution.II. Treat the solution of gold + other metals with a reducing agent and filter.III. You will obtain pure gold powder, separated from the solution of other metals.IV. Wash, dry, and granulate the gold powder.V. The final result will be your pure gold grain.

- Granulating machine

- Aqua regia gold refining and sedimentation machine/system

Aqua Regia gold refining and sedimentation machine

Step one: The base chemicals, concentrated hydrochloric acid and concentrated nitric acid are mixed together:

Au: Metallic gold